Thick-Wall Molding Technology

Purpose of development

Compared to hydraulic injection molding machine, electric injection molding machine has higher stability of injection speed and position accuracy, and is suitable for precision molding. However, for thick-wall molding, stable holding pressure needs be applied for a long time. As electric servo motor has limited capability in terms of loading time, sometimes what could be molded by the hydraulic machine may not be possible by the electric machine. Niigata's "Long time holding pressure control" enhances molding performance for thick-wall parts.

When injection speed that is as fast as regular molding is applied for thick-walled parts, defects such as weld marks, jetting and flow marks are often found. In order to prevent such defects, very slow injection speed of 1 mm/sec is required during filling process. "Ultra-low speed injection control" provides effective solutions for stability and accuracy of low speed injection.

Long-Term Pressure Holding Technology

1. Hold Pressure Vibration Control(H.P.V. Control)

Keeping holding pressure for a long duration of time becomes possible by repeating slight forward/reverse rotation of injection ball screw which keeps kinetic friction thus reduces motor load.

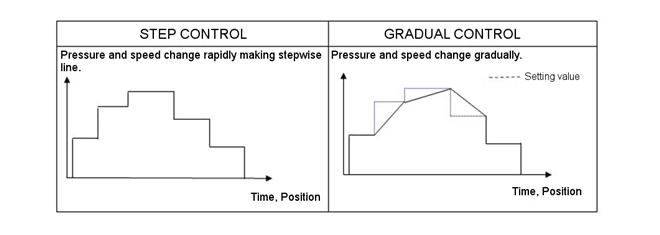

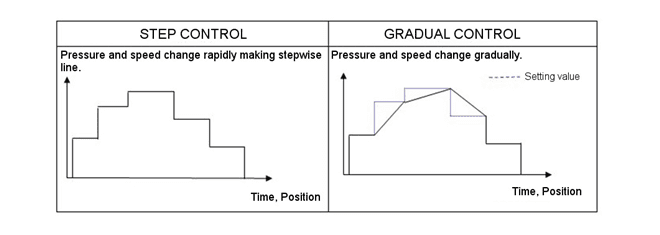

2.Gradual Control of Holding Pressure

By changing holding pressure gradually, resin filling progress can be adjusted with gate seal time. Holding pressure is kept optimum and motor overload is prevented.

3.High Precision Pressure Control

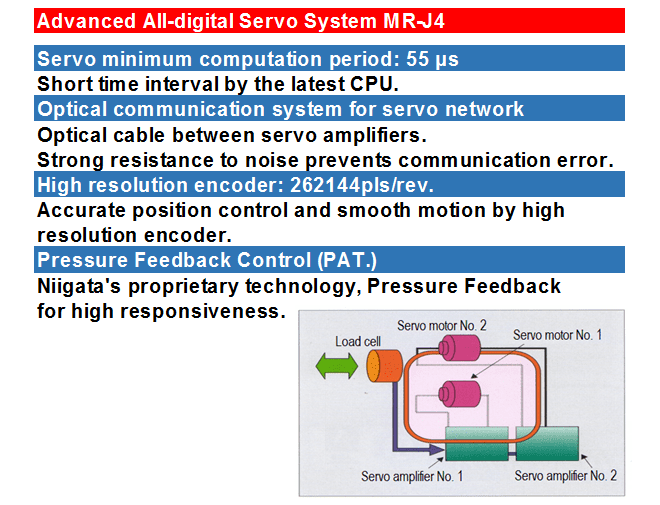

4.High Pressure Responsiveness

High responsiveness is achieved by servo amplifier directly controlling pressure feedback from digital load cell.

(*refer to Advanced All-Digital Servo System MR-J4)

(*refer to Advanced All-Digital Servo System MR-J4)

Ultra-Low Speed Injection Control

1.Screw Position Control with Slow Injection

Servo motor equipped with high resolution ender makes screw rotation stable even with ultra-low speed thus screw position control becomes highly accurate. (see Advanced All-Digital Servo System MR-J4)

2.Gradual Control of Injection Speed

Injection speed is controlled in gradual manner even at as slow as 1 mm/sec speed. Unlike hydraulic machine which receives pulsatory motion from pump, smooth speed change provides stable filling pressure that prevents weld marks, jetting and flow marks