MD-S7000 series

Middle Size All Electric Injection Molding Machine

Features

Point 1 Advanced injection unit and clamping unit

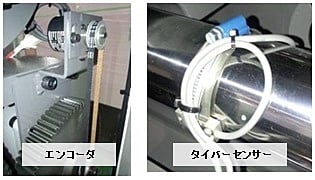

● Highly accurate clamping mechanism

Mold height detection encoder and tie bar sensor are installed for accurate clamping force.

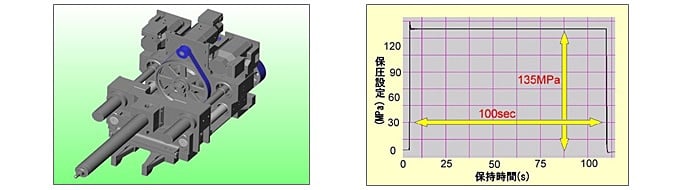

● Powerful injection

Holding time is longer than ever. 70~100 seconds at 135 MPa is possible with our standard screw size providing more than sufficient capability of thick-wall molding (*).

* Showed number is maximum capability and does not guarantee holding time during continuous molding.

* Showed number is maximum capability and does not guarantee holding time during continuous molding.

● Ultra low speed injection control

0.01 mm/s injection speed is possible by high resolution encoder. Advanced stability and repeatability are effective for thick-walled molding.

● BPF control Ⓡ (Balance Pressure Filling)

Screw temporarily stops during injection to adjust gate balance. Material flows without being forced and gas is released.

● CPF control (Constant Pressure Filling)

Filling speed is slowed down by controlling maximum filling pressure. As peak pressure is reduced when filling process is completed, it changes to the next holding process smoothly without sudden change.

Point 2 Efficient set up process

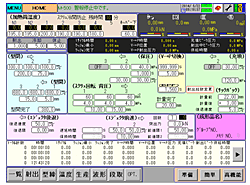

● NHN (Niigata Hiper Navi)

Integrated information on 1 screen.

・Preparation screen assists molding set up.

・Basic settings can be done on Easy setting screen.

・Advanced setting screen is for detailed configuration.

・Basic settings can be done on Easy setting screen.

・Advanced setting screen is for detailed configuration.

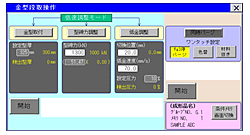

● Simple mold set up

・Mold attachment, clamping force adjustment and low pressure mold protection can be done by simple procedure.

Point 3 running cost reduction, maintenance-related improvement

● Reduced grease usage

・With high sealed ball screw, grease usage is reduced significantly.

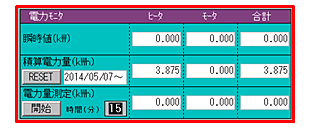

●Visualized running cost

・Energy consumption is shown on display.

・Molding monitor displays energy consumption per 1 shot.

●Enhanced reliability

・Control panel is more secured.

・IEC IP52 equivalent operation box.

・Maintenance reminder

Specifications

▼Contact

Inquiry Form

TEL.

+81-25-274-5130